Electron beam welding process - Air Liquide Welding

Electron beam welding process - Air Liquide Welding

Electron beam welding process - Air Liquide Welding

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

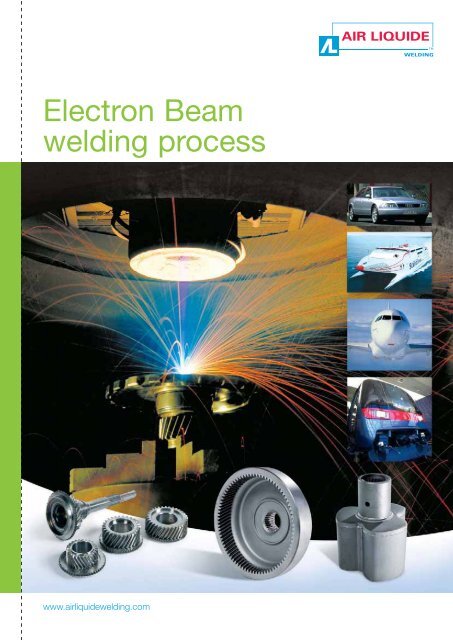

<strong>Electron</strong> Beam<br />

<strong>welding</strong> <strong>process</strong><br />

www.airliquide<strong>welding</strong>.com

<strong>Electron</strong> <strong>beam</strong> <strong>welding</strong> general presentation<br />

The principle of electron <strong>beam</strong> <strong>welding</strong> is relatively simple:<br />

electrons are accelerated by a high difference electrical<br />

potential and concentrated on a target. The electron’s kinetic<br />

energy is then transformed, for the most part, into thermal<br />

energy melting the metal and producing welds.<br />

The electron emission<br />

Some materials such, tantalium or hexaboride<br />

of lanthanum allow to get an appropriate quantity of free<br />

electrons when they are,heated up to a high<br />

temperature, and are used for emissive gun elements<br />

manufacturing.<br />

Inside electron guns these emissive elements can be<br />

heated up by two different modes:<br />

• direct heating by joule effect,<br />

• indirect heating by use of an electron bombardment<br />

from a filament.<br />

Vacuum environment necessity<br />

The emissive element and the electrodes are placed in<br />

the gun. The piece to be welded is located in the <strong>welding</strong><br />

chamber.<br />

Since the collision of free electrons and gas molecule<br />

which would induce <strong>beam</strong> dispersion and a decrease in<br />

the carried power density, the gun and the piece to be<br />

welded are vacuum pumped.<br />

The dimension of the <strong>welding</strong> chamber depends on the<br />

dimension of the parts to be welded with its positioning<br />

equipment and can vary from few litres up to few ten m 3 .<br />

The electron acceleration<br />

In order to be extracted from the surface of the emissive<br />

element, the free electrons need to be submitted to a<br />

strenuous electrostatic field. The potential difference<br />

between the emissive element (cathode) and the<br />

opposite electrode (anode) allows to create this field,<br />

which accelerates the electrons by giving them a kinetic<br />

energy.<br />

Filament<br />

Cathode<br />

Filament heating voltage<br />

- +<br />

-<br />

Reference potential<br />

Bias Voltage<br />

-<br />

Accelerating<br />

voltage<br />

<strong>Electron</strong> Beam creation<br />

In the inter-electrode space, the electrodes geometry<br />

defines the electron trajectories. First, the electron <strong>beam</strong><br />

converges in the anode drilled in its center.<br />

Then, the <strong>beam</strong> continues by inertia and diverges.<br />

In order to be used for <strong>welding</strong>, the <strong>beam</strong> is focused by<br />

an exciting coil placed in the gun. The focus length is set<br />

up by current adjustment inside the focusing coil.<br />

Wehnelt<br />

Anode<br />

Focusing<br />

coil<br />

Target: parts<br />

to be welded<br />

+<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> indirect heating gun<br />

2

Since the beginning of the <strong>Electron</strong> Beam <strong>Welding</strong> <strong>process</strong> 40 years ago and its first<br />

dedicated application; the <strong>welding</strong> of tubular fuel elements of nuclear cells; <strong>Electron</strong> <strong>beam</strong><br />

<strong>welding</strong> has since being used world-wide and its range of applications extends from<br />

<strong>welding</strong> thin foil to workpieces with walls over 100 mm thick.<br />

<strong>Electron</strong> Beam <strong>process</strong><br />

The electrons are small particles of matter with small mass.<br />

When they are accelerated they hit the piece transferring<br />

their kinetic energy into thermal energy ensuring metal<br />

melting creating plasma of metallic vapours.<br />

The E.B. <strong>welding</strong> <strong>process</strong> is a high energetic <strong>process</strong><br />

allowing to use very high power up to ten's of kW<br />

on small surfaces of 5/10 of mm diameter.<br />

However, the total heat input is actually much lower<br />

than that of any arc <strong>welding</strong> <strong>process</strong>.<br />

❯ 2 strips stainless steel of 0.1 mm thickness<br />

❯ Overlapping welds<br />

❯ 13% chrome steel<br />

❯ 20 mm thickness<br />

❯ One pass<br />

penetration butt<br />

<strong>welding</strong><br />

❯ <strong>Welding</strong> speed<br />

1 m/min<br />

❯ Power 10.3 kW<br />

Principals advantages of the electron <strong>beam</strong><br />

<strong>welding</strong> <strong>process</strong>:<br />

• very small deformations after <strong>welding</strong>,<br />

• very thick materials (exceeding 60 mm with steel) in one pass,<br />

• possibility to weld all the steel, copper, nickel materials, aluminium,<br />

metals sensitive to oxygen and other gases as zirconium, titanium…<br />

• no filler metal and no gas,<br />

• high <strong>welding</strong> quality. The welds obtained are exceptionally pure,<br />

• high reliability,<br />

❯ Zirconium Zr2 of 10 mm thickness<br />

❯ Fillet weld<br />

❯ Total penetration 14.2 mm<br />

❯ <strong>Welding</strong> speed 1 m/min<br />

❯ Power 7.2 kW<br />

• high reproducibility,<br />

• high productivity.<br />

3

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> answer:<br />

<strong>Electron</strong> Beam <strong>welding</strong> equipment<br />

A large range of solutions<br />

The specific chamber, tools and vacuum system have<br />

to be defined according to the piece characteristics and<br />

the needs in term of quality and quantity.<br />

For that, we will define jointly your specific requirement<br />

in term of:<br />

• piece characteristics with drawing and especially<br />

joint definition,<br />

• grade steel (chemical composition),<br />

• the required quantity (pieces/hour),<br />

• criteria of acceptability,<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> offers:<br />

• In term of production rate some Turn tables to load<br />

in masked time, robot for handling...<br />

• In term of <strong>process</strong> quality, Recorder, Video control<br />

(<strong>process</strong>), Beam deflection.<br />

Thanks to our experienced teams, we can respond<br />

to yours specifics need.<br />

Examples of a universal <strong>welding</strong> chamber for automotive<br />

application (gear-wheels...)<br />

136 litres (580 mm x 500 mm x 470 mm)<br />

ST Standard<br />

gun based on<br />

a motorized<br />

displacement<br />

carriage.<br />

One manual<br />

closing door<br />

equipped with<br />

2 viewing<br />

windows.<br />

Two<br />

Headstocks.<br />

Remote control box<br />

Start gun shot<br />

Axis displacement choice<br />

Focalisation current set<br />

Axis displacement<br />

hand crank<br />

Emergency Stop<br />

End gun shot<br />

Beam current set<br />

Central system control by CNC<br />

Based on its long experience, <strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong><br />

developed a specific software dedicated to the E.B.W<br />

<strong>process</strong> which controls the overall machine operation.<br />

Through a C.N.C, it manages:<br />

• The operation cycle,<br />

• The vacuum system,<br />

• The numerised axis,<br />

• The main parameters through the E.B.Generator.<br />

A control panel will receive the general controls of the<br />

machine (Automatic cycle start/stop, <strong>welding</strong> chamber<br />

venting…) and can on demand be modified to accept<br />

the specific control required by the customer.<br />

A very useful remote control box permits to modify the<br />

current of the focalisation and the current <strong>beam</strong> closed<br />

to the <strong>welding</strong> chamber. Thus, through the viewing<br />

window, it makes easier set up of <strong>welding</strong> parameter.<br />

4

Intensive working for over 35 years<br />

in industries<br />

All our E.B generators are low voltage triode gun. It gives<br />

many advantages as:<br />

• A <strong>beam</strong> a little bit thicker and consequently a much<br />

larger tolerance in the preparation of the edge to be<br />

welded.<br />

• Low emission of X rays parasite.<br />

Moreover, our solid cathodes are heated indirectly and are<br />

made from W in some case (Zirconium <strong>welding</strong>) and more<br />

generally in LaB6 material. These last materials present the<br />

characteristic to work at low temperature compared to<br />

other materials such as W or Ta. It offers a very long life<br />

from 1000 hours up to 2000 hours in comparison with<br />

the common consumable parts of industrial electron <strong>beam</strong><br />

generator. Moreover, the electrodes have a short coupling.<br />

It confers to the gun a very good stability of electronic<br />

trajectories and a good repeatability of the impact position.<br />

ST Standards series:<br />

autonomous E.B generator<br />

Our ST Standard gun<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> proposes a large range of<br />

autonomous electron <strong>beam</strong> <strong>welding</strong> generator from<br />

6 kW - 45 kV to 100 kW - 100 kV made up of:<br />

• Our triode gun with indirect cathode heating,<br />

• Our high voltage resonance power supply<br />

assembly with oil free and auxiliary tank,<br />

• A high voltage cable with low capacitance.<br />

An electrical cabinet with all the control loop of<br />

the <strong>process</strong>, a P.L.C, and a control box to set all<br />

the fundamentals E.B.W parameters.<br />

Thus, our E.B.Generator can work alone or under<br />

control of our C.N.C. In this way, the maintenance is<br />

made easier and on the other hand, we can on<br />

demand realize refurbishment on existent machine.<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> automous E.B generator<br />

(High voltage cable not represented)<br />

5

Think different: Think <strong>Electron</strong> Beam <strong>welding</strong><br />

A new fashion to design your pieces<br />

The wide range of energy density of the electron <strong>beam</strong> allows to readily obtain<br />

sound welds, presenting satisfactory mechanical characteristics and almost<br />

without any deformation, on materials for which a conventional <strong>welding</strong> <strong>process</strong><br />

would be extremely complex, or even impossible, to perform:<br />

Integral machined piece<br />

Cost Reduction<br />

100 mm thickness titanium butt weld<br />

The same piece welded by E.B.W<br />

Fillet welds of stainless steel<br />

Total penetration without deformation<br />

Up to 2 pieces welded by minute<br />

possible on this kind of application.<br />

6

<strong>Electron</strong> Beam <strong>welding</strong> activity<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> is part of the <strong>Air</strong> <strong>Liquide</strong> group the world<br />

leader in industrial and medical gases and related services.<br />

The group offers innovative solutions based on constantly<br />

enhanced technologies to help manufacture many indispensable<br />

products and preserve life.<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> experience<br />

The electron <strong>beam</strong> <strong>welding</strong> installations offered by<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> is the result of the integration of<br />

the technologies developed and the experience gained<br />

from our industrial achievements over the last thirty five<br />

years in electron <strong>beam</strong> technology.<br />

<strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> has many more references in<br />

electron <strong>beam</strong> <strong>welding</strong> in technological environment<br />

known through the trademark SAFMATIC as varied as:<br />

• aeronautics,<br />

• mechanic, hydraulic, pneumatic components,<br />

• motorcar automobile,<br />

• nuclear,<br />

• boiler construction.<br />

Consequently the elements of our installation have<br />

already met the many functioning criteria required in<br />

those demanding<br />

industrial contexts.<br />

The optimization<br />

of technical<br />

characteristics due<br />

to those different<br />

applications has<br />

lead to a high level<br />

of stability and<br />

reliability which is<br />

well appreciated<br />

by our Customer.<br />

<strong>Electron</strong> Beam <strong>welding</strong> workshop<br />

Project feasibility<br />

and small size production<br />

Our means of production and our means of control are<br />

at your service for prototypes and small quantities<br />

production.<br />

Machine<br />

12 kW maxi.<br />

Controlled<br />

by micro-computer<br />

10 kW maxi.<br />

Controlled<br />

by micro-computer<br />

Characteristic<br />

Enclosure: 24 dm 3<br />

Controlled axis for radial <strong>welding</strong><br />

Enclosure: 900 x 400 x 400<br />

Controlled axis for axial and radial <strong>welding</strong><br />

Benefit from the research<br />

department of <strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong><br />

Our research and development team is composed of<br />

more than 140 persons working to develop innovative<br />

solutions in:<br />

• metallurgy,<br />

• health and safety,<br />

• productivity,<br />

• gas, equipment,<br />

• consumables and<br />

tool combinations.<br />

6 kW maxi.<br />

Controlled<br />

by micro-computer<br />

Enclosure: 520 x 410 x 460<br />

Controlled axis for axial and radial <strong>welding</strong><br />

Innovation is a state of mind for the group employees.<br />

This is clearly illustrated through the many patented<br />

inventions developed by our researchers in the CTAS<br />

(Technical Centre for <strong>Welding</strong> Applications) the largest<br />

private research centre for <strong>welding</strong> and cutting technologies.<br />

7

Contacts<br />

BELGIUM<br />

AIR LIQUIDE WELDING BELGIUM SA<br />

Z.I. West Grijpen - Grijpenlaan 5 - 3300 TIENEN<br />

Tel.: +32 16 80 48 20 - Fax: +32 16 78 29 22<br />

CHINA<br />

SAF SHANGHAI REP.OFF.<br />

Rm 722 Pine City Hotel<br />

777 Zhao Jia Bang Lu - SHANGHAI 200032<br />

Tel.: +86 21 64 43 89 69 - Fax: +86 21 64 43 58 97<br />

CZECH REPUBLIC<br />

AIR LIQUIDE CZ S.R.O. - <strong>Welding</strong> and Cutting<br />

Podnikatelská 565 - Areál SVUM - 190 11 PRAHA 9 - Búchovice<br />

Tel.: +420 274 023 163 - Fax: +420 274 023 233<br />

FRANCE<br />

AIR LIQUIDE WELDING FRANCE<br />

13, rue d’Épluches - BP 70024 Saint-Ouen l'Aumône<br />

95315 CERGY PONTOISE Cedex<br />

Tel.: +33 1 34 21 33 33 - Fax: +33 1 34 21 31 30<br />

GERMANY<br />

OERLIKON SCHWEISSTECHNIK GmbH<br />

Industriestrasse 12 - D-67304 EISENBERG/PFALZ<br />

Tel.: +49 6351 4760 - Fax: +49 6351 476 335<br />

HUNGARY<br />

AIR LIQUIDE HUNGARY - <strong>Welding</strong> & Cutting<br />

Krisztina krt. 39/b - H-1013 BUDAPEST<br />

Tel.: +36 1 339 8650 - Fax: +36 1 339 8649<br />

ITALY<br />

AIR LIQUIDE WELDING ITALY<br />

Via Torricelli 15/A - 37135 VERONA<br />

Tel.: +39 045 82 91 511 - Fax: +39 045 82 91 536<br />

LUXEMBOURG<br />

AIR LIQUIDE WELDING LUXEMBOURG S.A.<br />

5 rue de la Déportation - BP 1385 - L-1415 LUXEMBOURG<br />

Tel.: +352 48 54 56 - Fax: +352 48 54 57<br />

MALAYSIA<br />

SAF-OERLIKON MALAYSIA SDN BHD<br />

No 10, Jalan TPP 5/1<br />

Taman Perindustrian Puchong - 47100 PUCHONG, SELANGOR<br />

Tel.: +603 8060 8638 - Fax: +603 8061 620<br />

NETHERLANDS<br />

AIR LIQUIDE WELDING NETHERLANDS<br />

Rudonk 6 B - NL 4824 AJ BREDA<br />

Tel.: +31 76 541 00 80 - Fax: +31 76 541 58 96<br />

POLAND<br />

AIR LIQUIDE WELDING POLSKA - SP. Z.o.o<br />

UL. Porcelanowa 10 - 40-246 KATOWICE<br />

Tel.: +48 32 609 04 50 - Fax: +48 32 609 04 60<br />

ALW Export Department Italy<br />

Via Torricelli15/A<br />

37135 VERONA<br />

Tel.: +39 045 82 91 511- Fax: +39 045 82 91 536<br />

E-mail: export.alwitaly@airliquide.com<br />

Contacts for other countries<br />

ALW Export Department France<br />

13, rue d'Epluches<br />

BP 70024 Saint Ouen l'Aumône<br />

95315 CERGY-PONTOISE Cedex<br />

Tel.: +33 1 34 21 33 33 - Fax: +33 1 30 37 19 73<br />

E-mail: export.alwfrance@airliquide.com<br />

PORTUGAL<br />

AIR LIQUIDE SOLDADURA LDA<br />

Rua Dr. António Loureiro Borges, 4-2° Arquiparque<br />

Miraflores - 1495-131 ALGÉS<br />

Tel: +351 21 41 64 900 - Fax: +351 21 41 69 40<br />

ROMANIA<br />

DUCTIL<br />

Aleea Industriilor Nr 1 - 120224 BUZAU<br />

Tel.: +40 238 722 058 - Fax: +40 238 716 861<br />

RUSSIA<br />

AIR LIQUIDE WELDING<br />

17 Vorontsovskaya Str. - 109147 MOSCOW<br />

Tel.: +7 495 641 28 98 - Fax: +7 495 641 28 91<br />

SCANDINAVIA<br />

OERLIKON SKANDINAVIEN AB<br />

Krossverksgatan 7 - 216 16 LIMHAMN<br />

Tel.: +46 (0)40 670 15 00 - Fax: +46 (0)40 670 15 01<br />

SLOVAKIA<br />

AIR LIQUIDE WELDING CENTRAL EUROPE S.R.O.<br />

Hlohovecká 6 - 951 41 NITRA - LUŽIANKY<br />

Tel.: +421 37 692 4610 - Fax : + 421 37 651 28 04<br />

SPAIN<br />

OERLIKON SOLDADURA SA<br />

Poligono Industrial la Noria Carretera de Castellon<br />

Km-15,500 - 50730 El Burgo de Ebro - ZARAGOZA<br />

Tel.: +34 976 10 47 00 - Fax: +34 976 10 42 67<br />

SWITZERLAND<br />

OERLIKON SCHWEISSTECHNIK AG<br />

Mandachstrasse 54 - CH 8155 NIEDERHASLI<br />

Tel.:+41 44 3076 111 - Fax: +41 44 3076 112<br />

THAILANDE<br />

AIR LIQUIDE WELDING THAILAND Co. Ltd.<br />

40 Moo 6 - Ramindra Road Km 9.5 - KHANNAYAO, BANGKOK 10230<br />

Tel.: +66 29 43 2250 - Fax: +66 29 43 2256<br />

UAE<br />

AIR LIQUIDE WELDING MIDDLE EAST FZE<br />

Jebel Ali free zone warehouse No. FZS1AH05<br />

P.O. BOX 18734 - Jebel Ali - DUBAI<br />

Tel.: +971(0)48861606 - Fax: +971(0)48861608<br />

U. K.<br />

AIR LIQUIDE WELDING Ltd<br />

Low March / London Road - DAVENTRY - Northants NN11 4SD<br />

Tel.: +44 1 327 70 55 11 - Fax: +44 1 327 70 13 10<br />

UKRAINE<br />

AIR LIQUIDE WELDING UKRAINE, Llc.<br />

1 rue Proskura - bureau 106A - 61070 KHARKOV<br />

Tel.: +380 577 546 867 - Fax: +380 577 546 867<br />

ALW Export Department Switzerland<br />

OERLIKON WELDING LTD<br />

Mandachstrasse 54<br />

CH - 8155 Niederhasli<br />

Tel.: +41 44 3076 111 - Fax: +41 44 3076 212<br />

E-mail: export.oerlikon<strong>welding</strong>@airliquide.com<br />

W 000 274 587 - © <strong>Air</strong> <strong>Liquide</strong> <strong>Welding</strong> - 03/2009 - Ed.1 - PLBD 5584<br />

www.airliquide.com<br />

Founded in 1902, <strong>Air</strong> <strong>Liquide</strong> is the world leader in industrial and medical gases and related services. The company has offices in 75 countries and employs a work force<br />

of 43.000. Drawing on constantly renewed technologies, <strong>Air</strong> <strong>Liquide</strong> develops groundbreaking solutions used in making countless everyday products and in helping to<br />

preserve life.