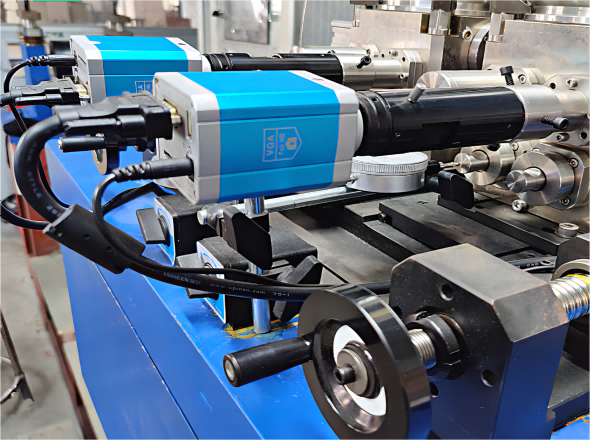

WHFL-60-50-2(0.1-1) Transverse Splicing Continuous Welding Electron Beam Welding Machine

WHFL-60-50-2(0.1-1) Electron Beam Welding Machine

- Alloy Strip Welding Thickness: 0.1mm to 1mm.

- Narrow weld: the depth to width ratio of the weld can reach 50:1.

- Welding Materials: Refractory Metals, Reactive Metals, Dissimilar Metals.

| Brand | WHFL | Name | Transverse Splicing Continuous Welding Electron Beam Welding Machine |

| Model No. | WHFL-60-50-2(0.1-1) | Type | Welding Machine |

| Weight | 10000KG | Voltage | 60kV |

| Core Components | Electron beam emission source, high voltage power supply | Guarantee Period | One Year |

| Current | 25mA | Rated Capacity | 55kw |

| Duration of Rated Load | 100% | Dimension | 10m x 30m |

| Product Use | Electron Beam Welding | Welded strip thickness | 0.1mm to 1mm |

| Basic Configuration | Production line | direct heat electron gun | domestic pump |

| Optional Configuration | Remote fault diagnosis,oil mist filter,defect identification,screw pump. and | IT2.0 system Laibao pump,mains power failure protection system,weld quality identfication | Guarantee system 1.0 (difference),weld quality identification and guarantee system 2.0difference +expert database |

| Status | Brand New | Place of Origin | Wuhan, China |

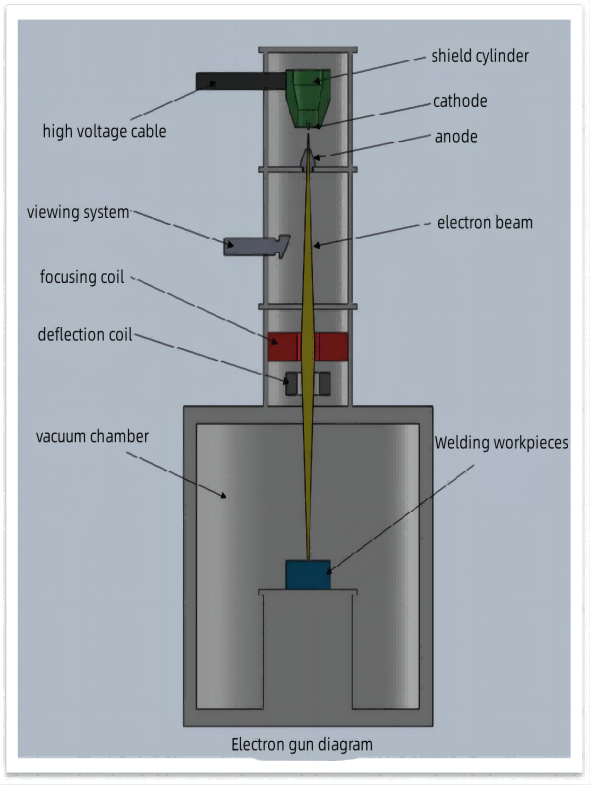

EBW Machine Technological Principle

When the cathode (generally pure tungsten material) in the electron beam generator (electron gun) is heated to a certain temperature, the electrons escape, and the electrons are accelerated in the high voltage electric field and focused through the electromagnetic lens, forming an electron beam with high energy density and close to the speed of light. When the electron beam bombards the surface of the weldment, most of the kinetic energy of the electron is converted into heat energy. The metal at the joint of the welding part is fused to achieve metal splicing.

Know more about the history of Electron beam welding.